Disassembling Robot

As a team of 6 students, we designed and prototyped a giant disassembling robot puzzle.

The design was in response to a prompt given by 5wits Adventures to create a puzzle, attraction, or experience to accompany a sci-fi themed adventure.

A concept sketch shows how the puzzle may greet adventurers: a pile of robot parts, begging to be reassembled. The head lights up and begins to speak: "I must be put back together to access my memory modules." When the robot is reassembled, he informs teams of how to move on to the next level, and upon their departure, falls apart so that he returns to his original state.

(my drawing)

I created a simulation to show how a robot held only by magnets may fall apart if they were turned off. This also provides a great visual to explain our team's vision:

(my rendering)

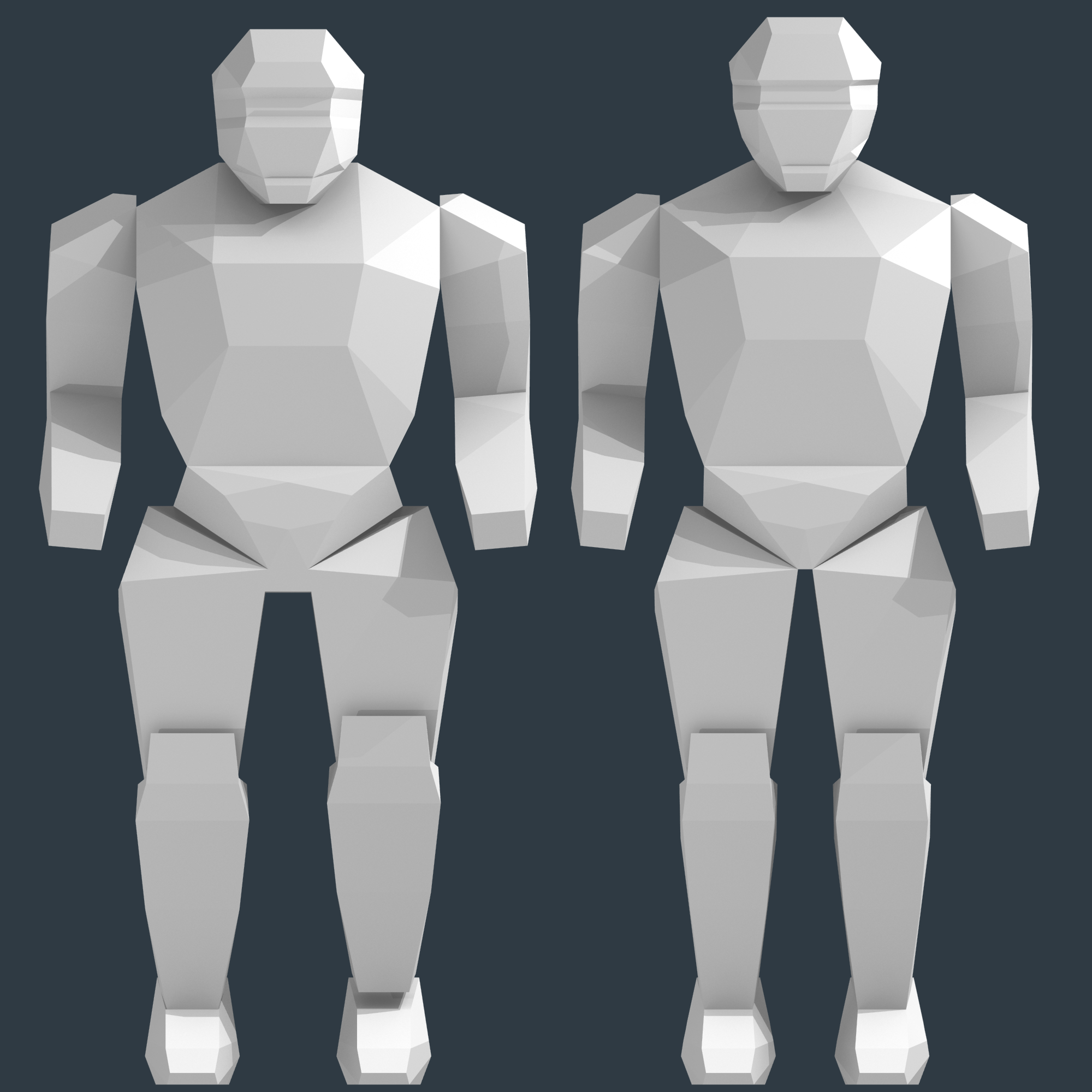

The robot, lovingly dubbed 'Percy' went through a series of design decisions. We considered both a smooth and faceted Percy, as well as the option of having him break apart into ruled parts or randomly sliced pieces. This video shows that:

(my rendering)

Ultimately, the faceted robot falling into ruled parts was seen as more credible by users and we continued with this design. Before moving on to prototyping however, I was tasked to address user feedback to make our 'gentle giant' more gentle. To make him look less imposing, he was made slimmer, eyes lifted up, his head less square, and moved up slightly to make him look less hunched.

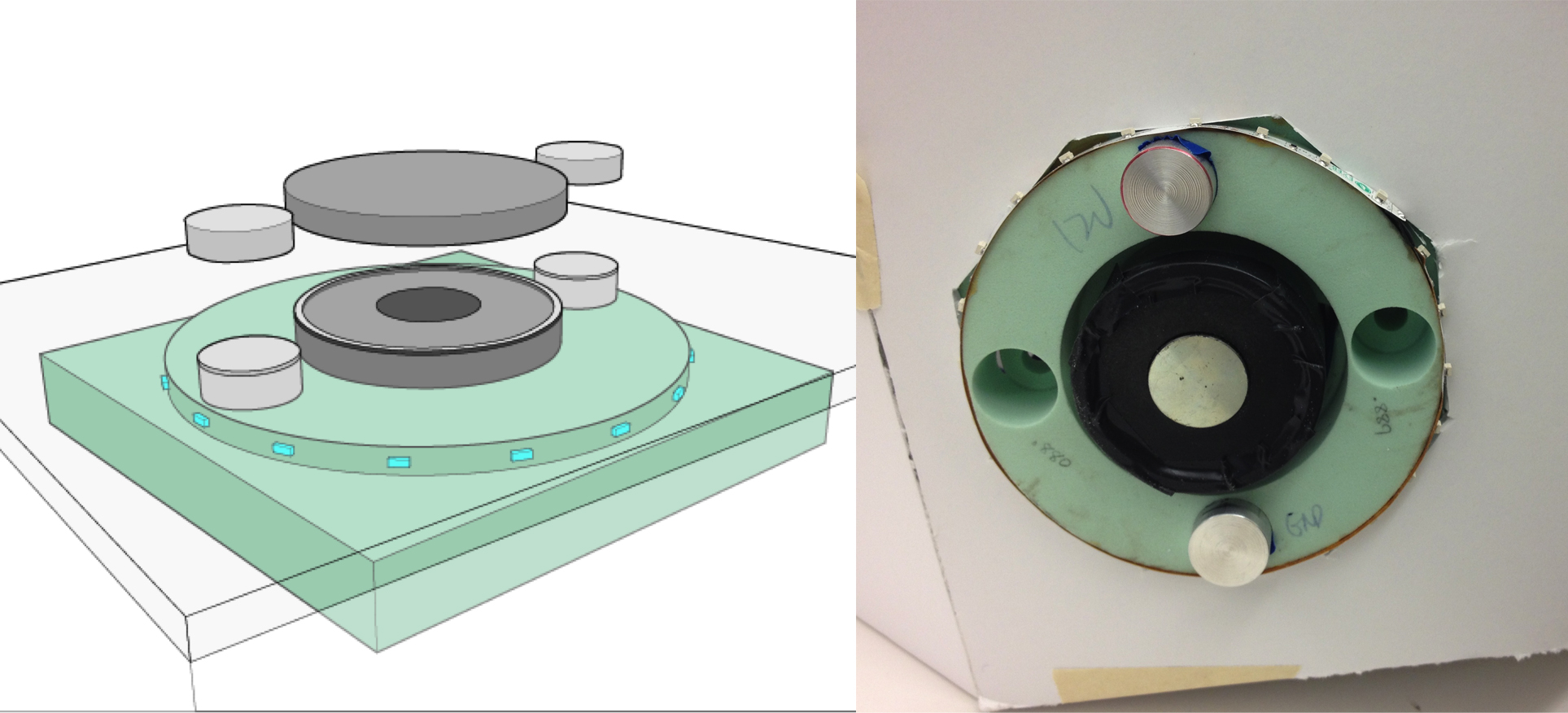

We decided that the best solution to make this design possible was to employ electromagnets. A simple diagram shows how two pieces would be assembled with electromagnets and contacts:

With a tight budget and time constraint we chose to use folded foam core to build the robot's casing. Using the open source software Pepakura, I created unfolded cut files for each part and milled the foam core on a 3-axis mill:

part example:

The prototype joints were assembled according to this diagram, with a central electomagnet and two contacts seated in milled hard foam. Finally, the joints are made interactive with a strip of LEDs along the foam, diffused through a layer of white acrylic:

The finished prototype stands by itself, thanks to magnetic force! When power to the electromagnets is cut, the pieces fall apart.

See it work!