Sports Bra Design Optimization

If you’re curious for more details, feel free to read my thesis or the more condensed published paper on this research:

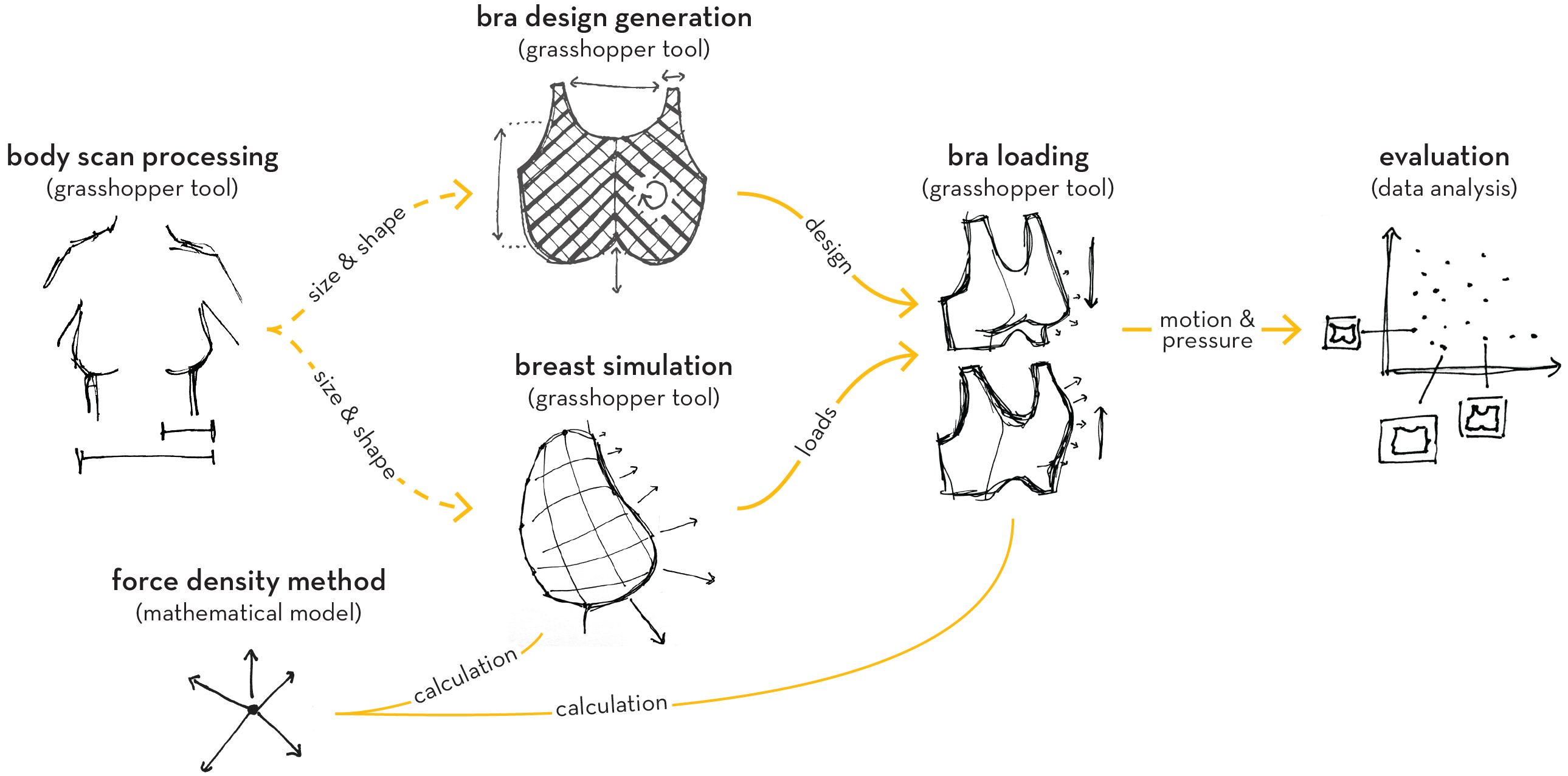

The goal of my masters thesis was to better understand the sports bra design space and how changes in designs could affect their performance objectives. In order to answer those questions, I created several software tools (in Grasshopper 3D) to: extract measurements from body scans, generate bra designs, simulate breasts, and test the generated designs according to the simulated breasts.

These tools and how they are used together are illustrated in this diagram:

Measuring and mapping body scans:

I created a grasshopper afnd python tool to automatically detect landmarks on (almost) any female body scan and applied it to a data set of 583 body scans.

Landmarks identified:

This resulted in numerical data on the body shape and size of (almost) 583 women, which I then performed simple machine learning analysis on to map body scans to 8 clusters based on band measurements and cup volume:

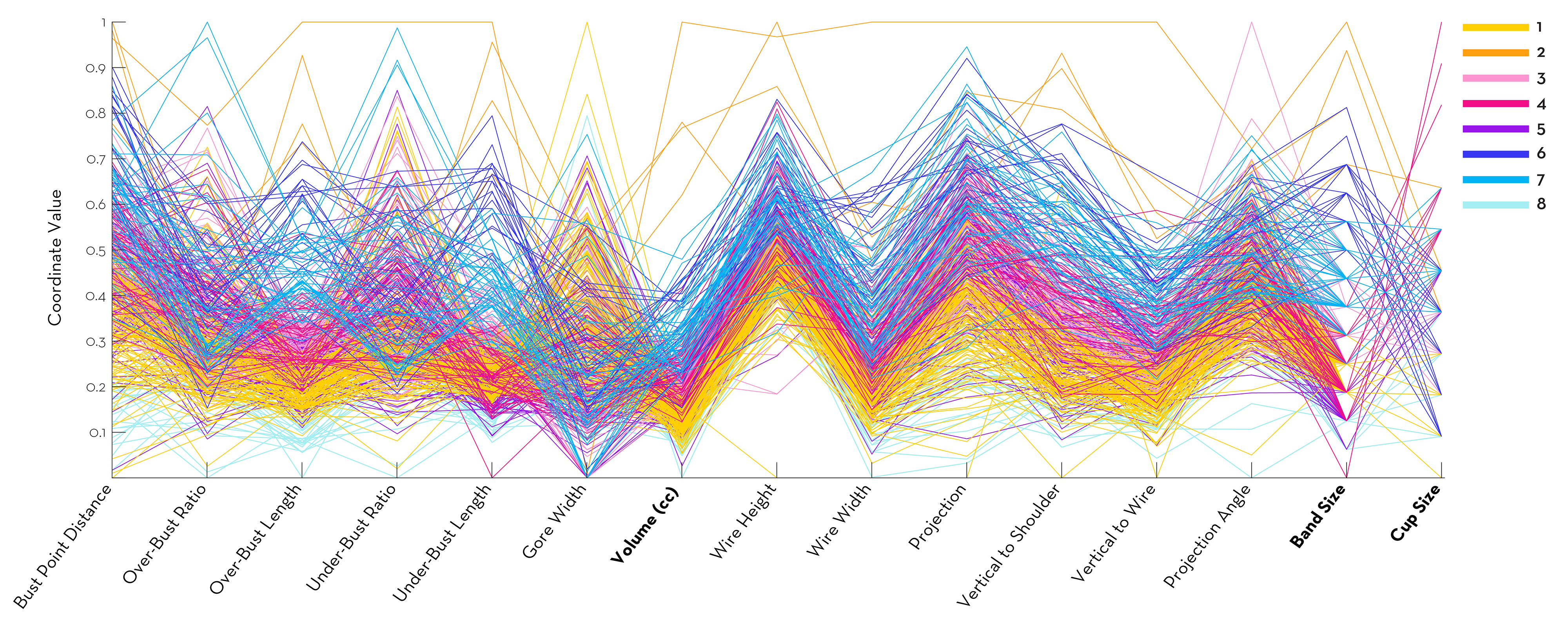

Parallel coordinate plot of body parameters

Averaged images of body scans to visualize clusters

Generating bra designs:

A large part of this research was to define new, scientifically motivated design directions for improving sports bra performance. While there are many objectives we can try to achieve to improve sports bras, I've focused on reduced range of breast motion and reduced average pressure.

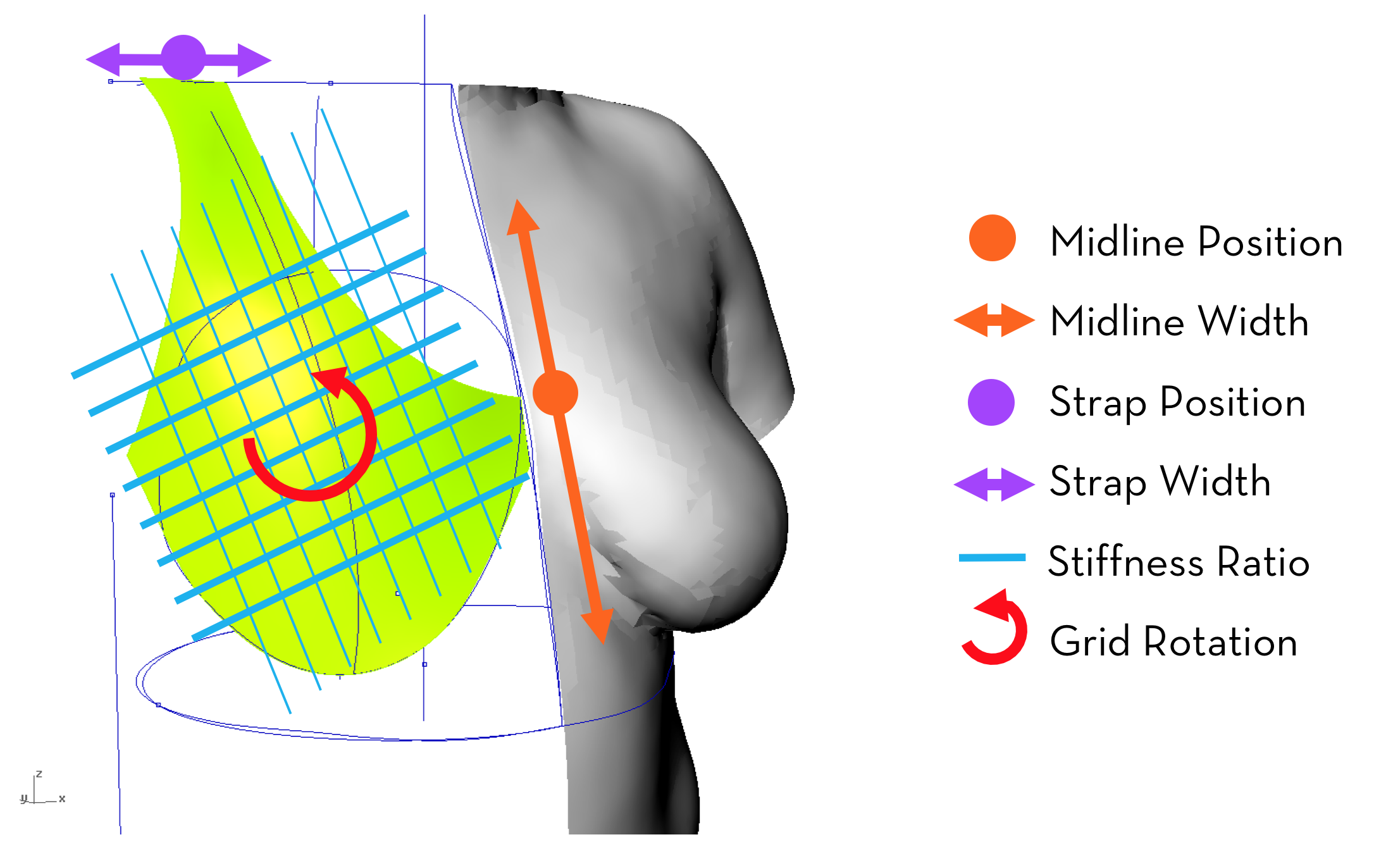

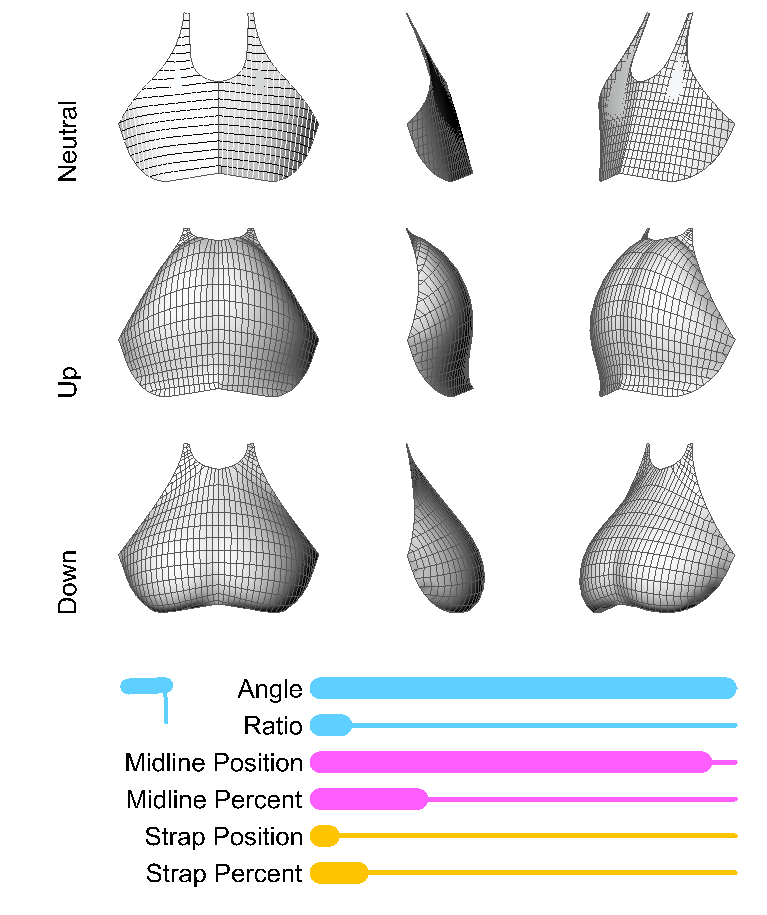

In order to understand the affect of different design parameters on bra performance, I needed to be able to create designs with specific parameters for testing, and create many of them to determine trends. I created a grasshopper tool to generate simplified bra designs based on 6 parameters:

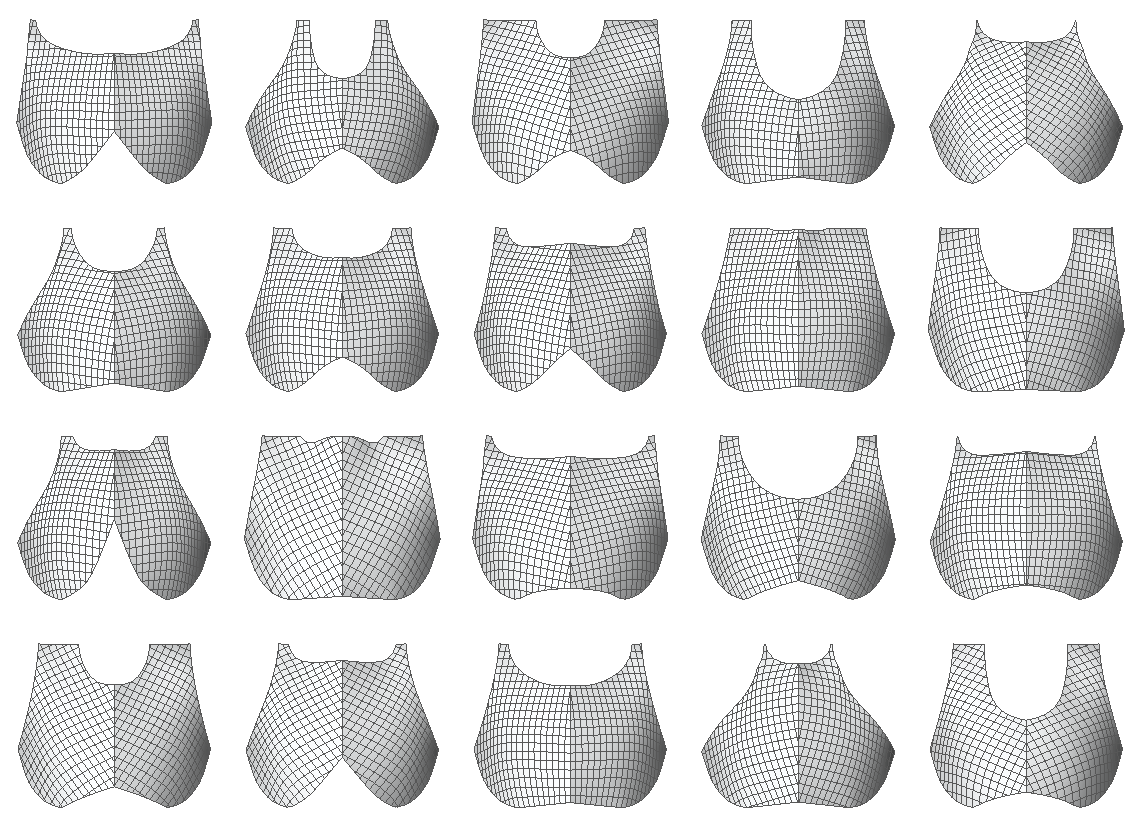

Here, you can see a sampling of some of the bras generated with the design tool:

Simulating breast loads:

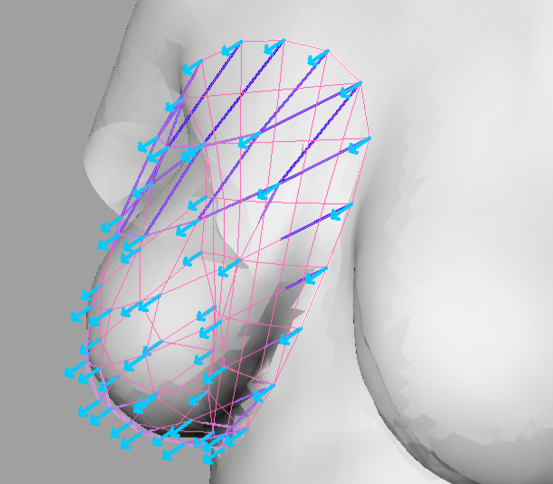

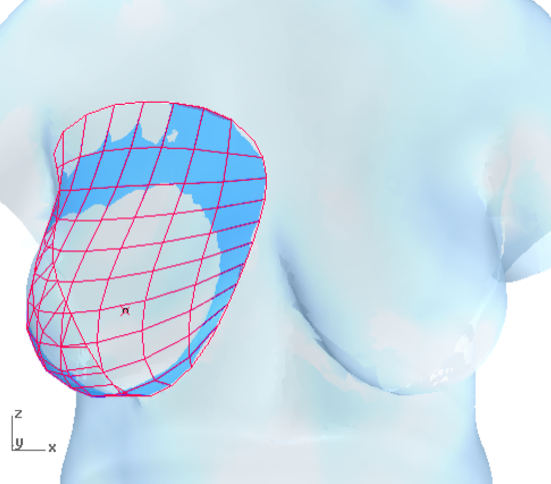

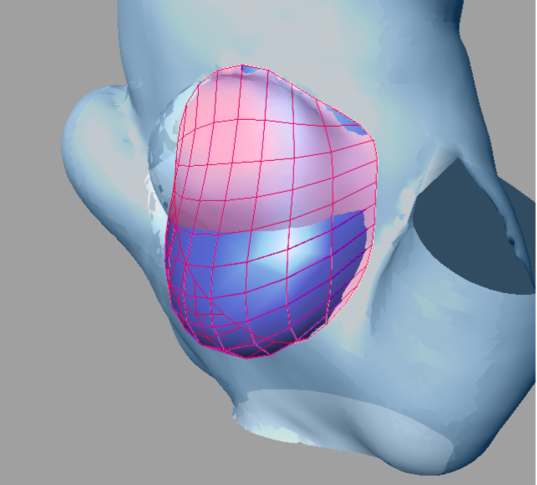

Breast and bra simulations were calculated using the force density method (FDM), which I implemented by writing a custom Grasshopper component in C# and Visual Studio.

These following images show an initial FDM breast with uniform loading, a later (more accurate) step with non-uniform loading representing hydrostatic pressure, and the same model when loaded upside down (this is used to test range of motion)

Evaluating performance:

Each bra design is then tested using data from our breast simulation, and their performance (estimated pressure and total movement between loading scenarios) is recorded. These tests can be visually checked using images saved by the tool. See for example, these three generated bras and their visually represented performance under each loading scenario:

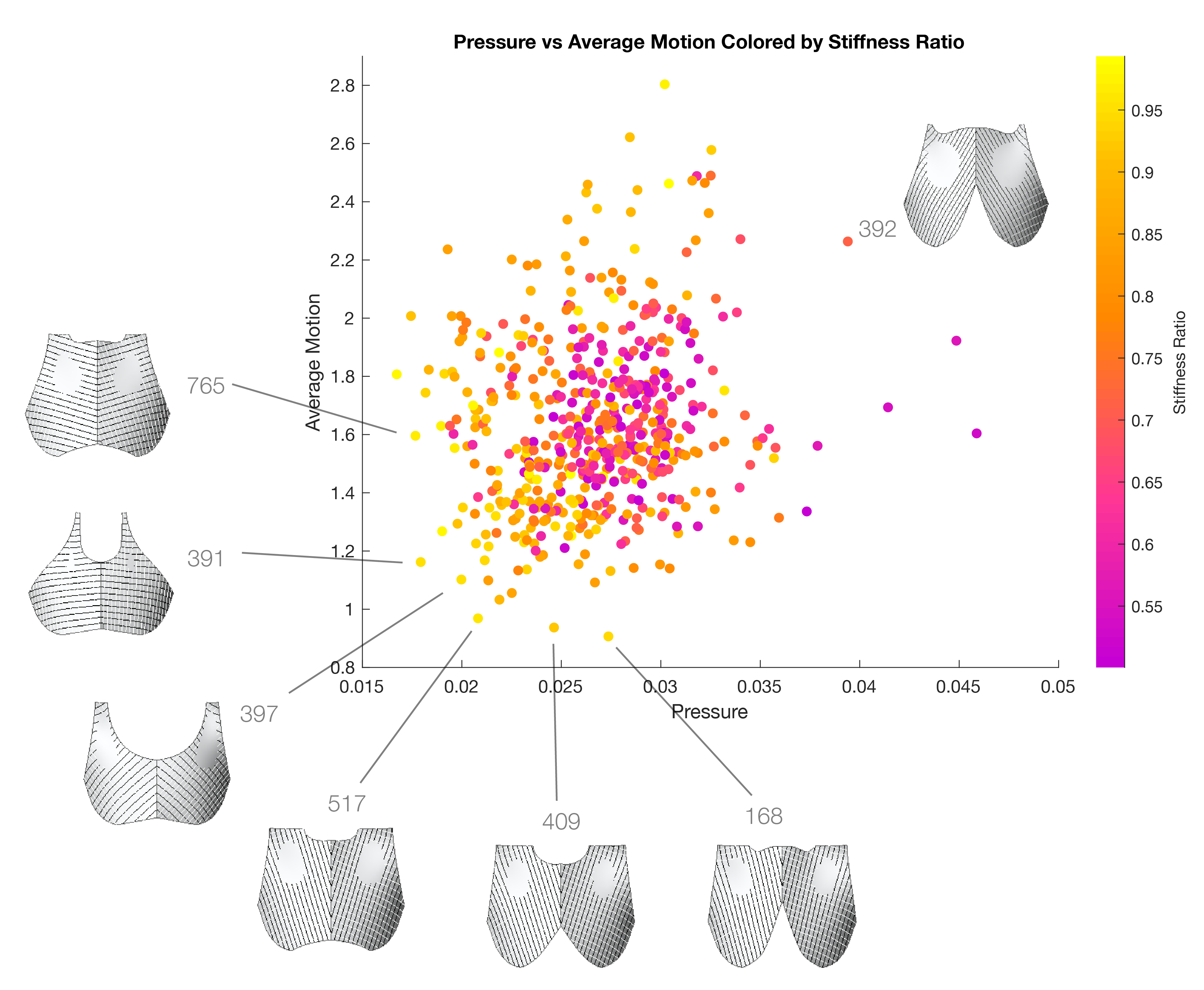

The performances of these designs can now be plotted against design variables to get a sense for how variables in the design process effect performance, and what designs could be optimal:

Additional 3-axis plots were generated to identify bi-variable impacts on performance results, with the most significant results suggesting that increased pressure was predicted for designs where stiffness was more distributed:

This diagram serves as a rubric for how the varying ratio and angle parameters relate to the relative stiffness (represented by stroke weight) of each direction of the mesh:

Stiff Sports Bra Design

In an effort to test how stiffness in sports bras could work towards their efficacy at reducing motion, I designed (in CAD) and fabricated several iterations of sports bra prototypes.

The initial inspiration for exploring stiffer bras came from considering examples of armor in comic book characters and movies. I'm sure I'm not the first to ask:

Armor-like bras is not entirely fiction. Encapsulated bras exist that are usually composites of molded foam, underwire, some stiff fabric, and some elastic fabric. These bras are usually marketed towards larger-breasted women because they are more supportive than their compression bra counterparts. They achieve armor-like stiffness thanks to underwires, molding, and often complex construction. Although they are typically more supportive, many women dislike the encapsulated bra style because they feel it is overbuilt.

Generative Custom Fit Design:

My hypothesis was that if the bra were custom designed to perfectly fit its wearer, then I could design a bra using developable stiff panels, removing the need for the underwires and molding of encapsulated bras. This would mean a bra with the benefits and support of an encapsulated bra, but the simplicity and lightness of a compression bra.

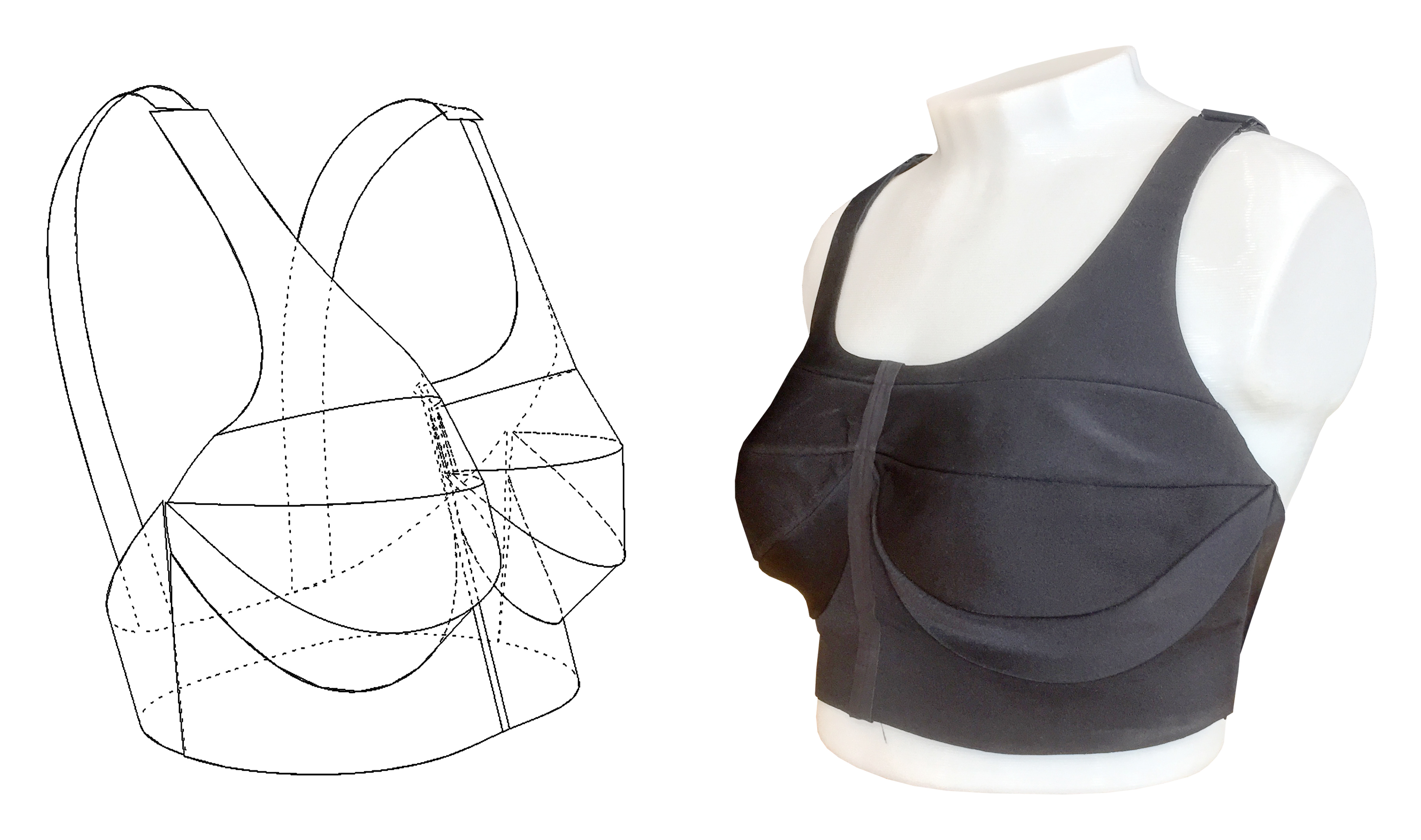

In order to fit a person perfectly, I created a tool in grasshopper to generate a bra design based on measurements from the intended user:

Initial Prototypes:

Using the grasshopper tool, I iterated through 3 prototypes before creating final bras to be tested. In order to fabricate these bra designs using stiff fabric, extra steps were taken in CAD to adapt the designs to developable panels that could be unrolled flat.

These 3 initial prototypes were critical to understanding how stiffness interacts with sports bras, and how bra shape can impact its effectiveness. These main learnings are bolded in the explanation below.

The first prototype (left) was made entirely from a non-stretch cotton fabric. Immediately, it was apparent that while the bra fit well, it did not provide much support. I realized that the tension provided by a stretched fabric around the torso and over the shoulders is necessary to counteract gravity, as well as looseness of skin (if you're curious - see how much your skin moves when you push it around).

Moving forward, all of our prototypes introduced this tension through an elastic back, but kept stiffness in the front of the bra. My second prototype (middle) tested targeted stiffness. It demonstrated that targeted stiffness won't work by itself, as leaving other areas bare will encourage movement to those areas.

The third prototype (right) was created to see how an incredibly thin and light material like Nylon would perform, given that it still met our requirements for stiffness. The bra fit well, and was more supportive than the first prototype, however it also showed that the shape of the cups needed to be redesigned. I had been designing the bra to match measurements and shape of someone in an everyday bra, so despite the added tension from having an elastic back, the cup shape was still encouraging the breasts to hang in a more "natural" and less supported way. Instead of designing cups to meet this natural breast shape, cups needed to be designed to meet the ideal breast shape under tension.

Final Prototypes and Testing:

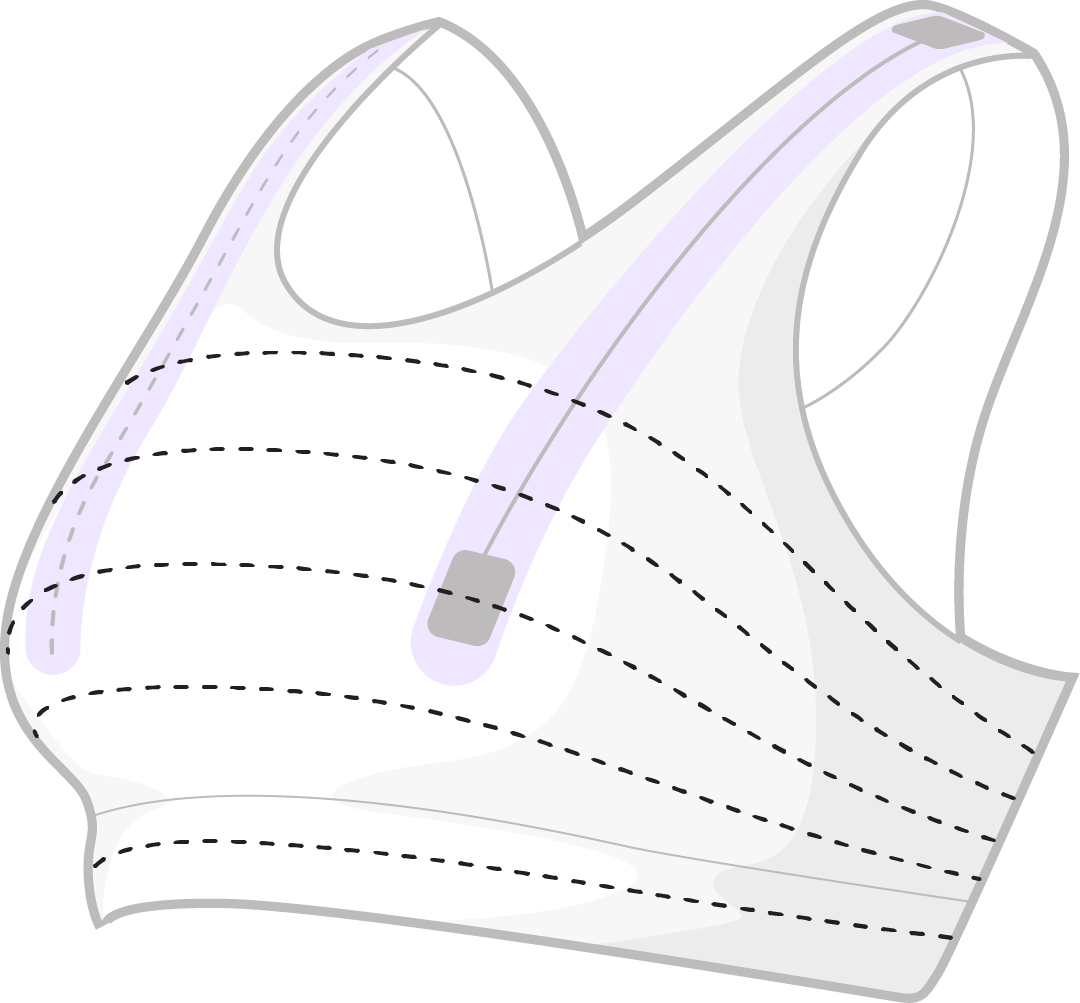

Taking into account my learnings from the three initial prototypes, I designed and fabricated two final prototypes (see below). The prototypes were identical, with the exception of the directional paneling being either horizontal or vertical. The straps in the prototypes were designed with multiple attachment points in order to allow for measurable adjustments in strap tightness. The prototypes were made by laser cutting the pieces, sewing them together using a flat stitch machine, and adding heat bonded trim to seams for comfort. The elastic backs for these bras were made of two layers of spandex, heat bonded together, for a technical feel and stronger performance.

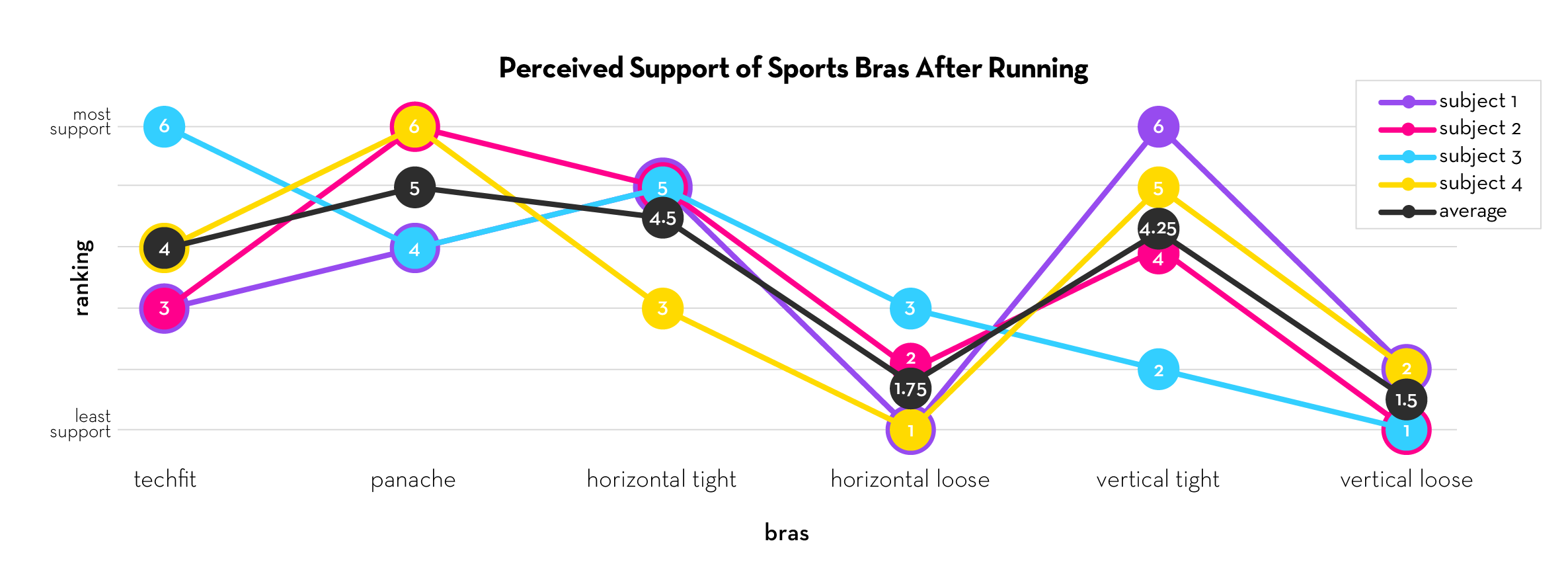

In order to get more empirical data on the role played by stiffness and tension in bras, I performed kinematic testing on these prototypes as well as industry standard bras: the adidas Techfit - a standard compression (stretchy) bra, and the Panache Underwire Sports Bra - a standard encapsulated (molded) bra. Four subjects were tested while running on a treadmill in each bra.

Although motion data was collected using a magnetic marker system, the results from that data were inconsistent and I was unable to make any conclusions from it. However, I also collected perception feedback from testers throughout the test using a survey and interview questions. Based on these answers, we saw that all testers perceived the bra prototypes are more supportive when they were adjusted to a tighter setting in the strap.

Without accurate motion data, it's hard to be conclusive about how these prototypes affected breast motion during exercise. However, it's incredibly promising that these prototypes, made by an amateur seamstress (me), could be tested alongside real sports bras, and be so positively received.

Rho Measurement Bra

Left to right: Sam Zaref, Kanika Kumar, Laurel Marcus, Me, Dan Barnes, Jennifer Beem

For MIT's graduate Product Development class 2.739, I worked on a team of 6 - 2 Mechanical Engineers (myself included), 2 Business Students, and 2 Designers from RISD - to conceptualize, design, and fabricate a breast density measurement bra.

(I made this diagram)

Right: First (bottom) and second (top) works like prototypes created by Jennifer and myself

Top left: a looks like prototype created by RISD students

Bottom left: Prototype of cast surrogates with different densities

I presented on some of the more technical aspects of our design during the final presentation:

And demonstrated our works like bra onstage:

Fast Assembly RC Car

2.810: Manufacturing Processes and Systems was a class in 2 parts:

Part one was learning about manufacturing, and part two was exercising that learning through a constrained manufacturing RC project, leading to a competitive race.

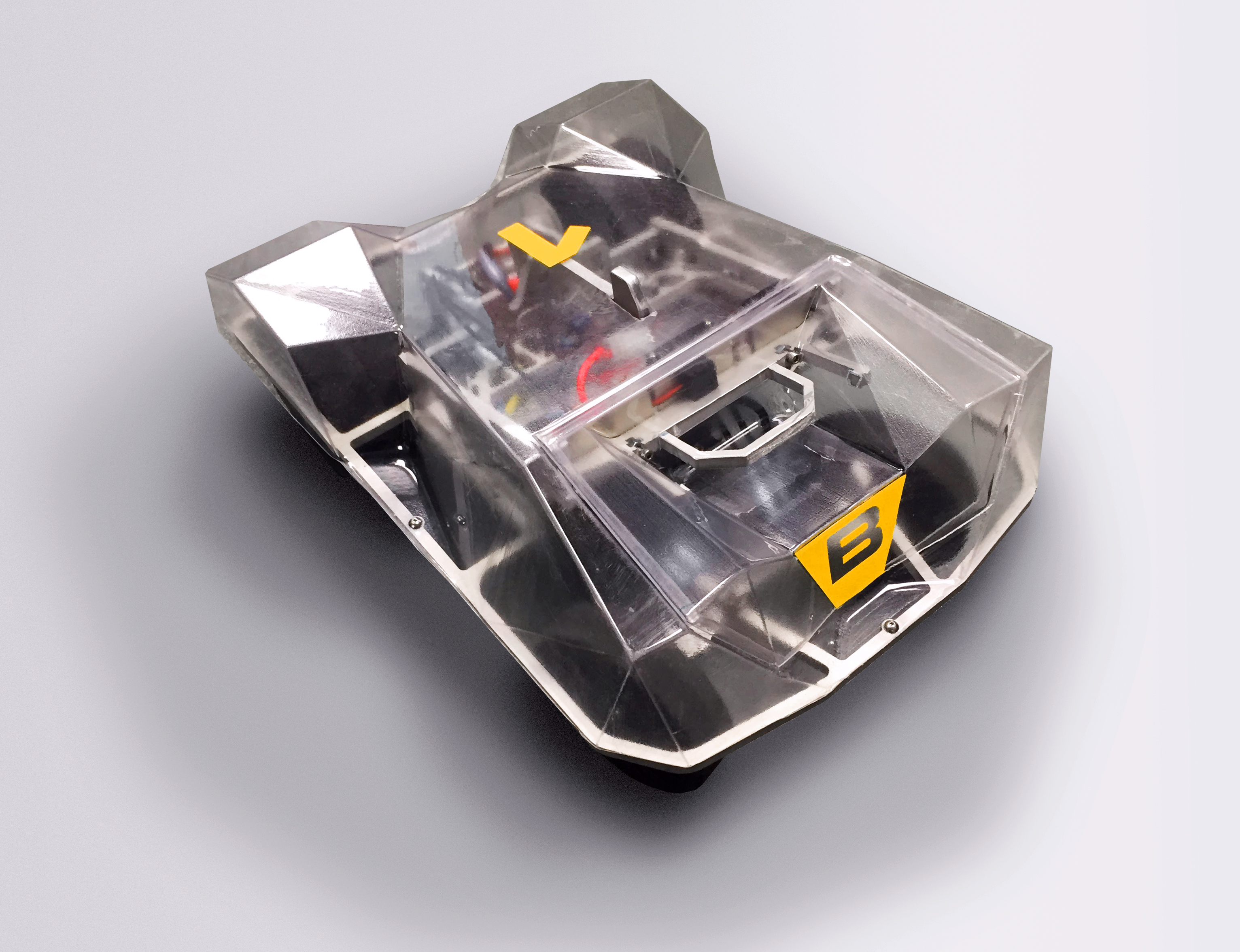

In this page, I'll cover the second part - designing, fabricating, assembling, and finally racing a fleet of RC cars! Here's our final result:

The car challenge has roughly the following constraints:

1) The team must make as many cars as there are team members

2) The car fleet must share one control + power hub, that will be swapped at each lap during the race

3) The chassis must be waterjet cut and fit within a prescribed footprint

4) The car must be enclosed in a thermoform shell

5) Wheel hubs will be injection molded, and wheels are limited in diameter

6) All motors and electrical components are provided and cannot be substituted

7) You may not exceed $20 of extra material spent per car.

Team B (after a crucial pre-race practice):

From left to right: Blake Cole, Aliza Khurram, Me, Michael Bell, Peter Godart, Sally Miller, William Sawyer

From left to right: Blake Cole, Aliza Khurram, Me, Michael Bell, Peter Godart, Sally Miller, William SawyerOur team (pictured above), was comprised of 7 Mechanical Engineering graduate students. From our first meeting, it was clear that we all had unique ambitions and exciting technologies that we wanted to contribute to our car, and we decided to throw caution to the wind and do them all.

These ambitions were:

A front decoupled suspension using spring steel flexures

A rear suspension through a spring loaded hinge for the rear drivetrain

Bowden cable steering, to allow for independent wheel suspension in the front wheels

Spring loaded "Cassette" control box design, for fast swapping between cars

A beautiful, well crafted, and carefully detailed 2 part thermoform shell design (my ambition)

Car shells made in previous years of the class were all designed as organic, rather blobby forms, and I wanted to create something wildly different.

Examples of previous thermoform molds from the class:

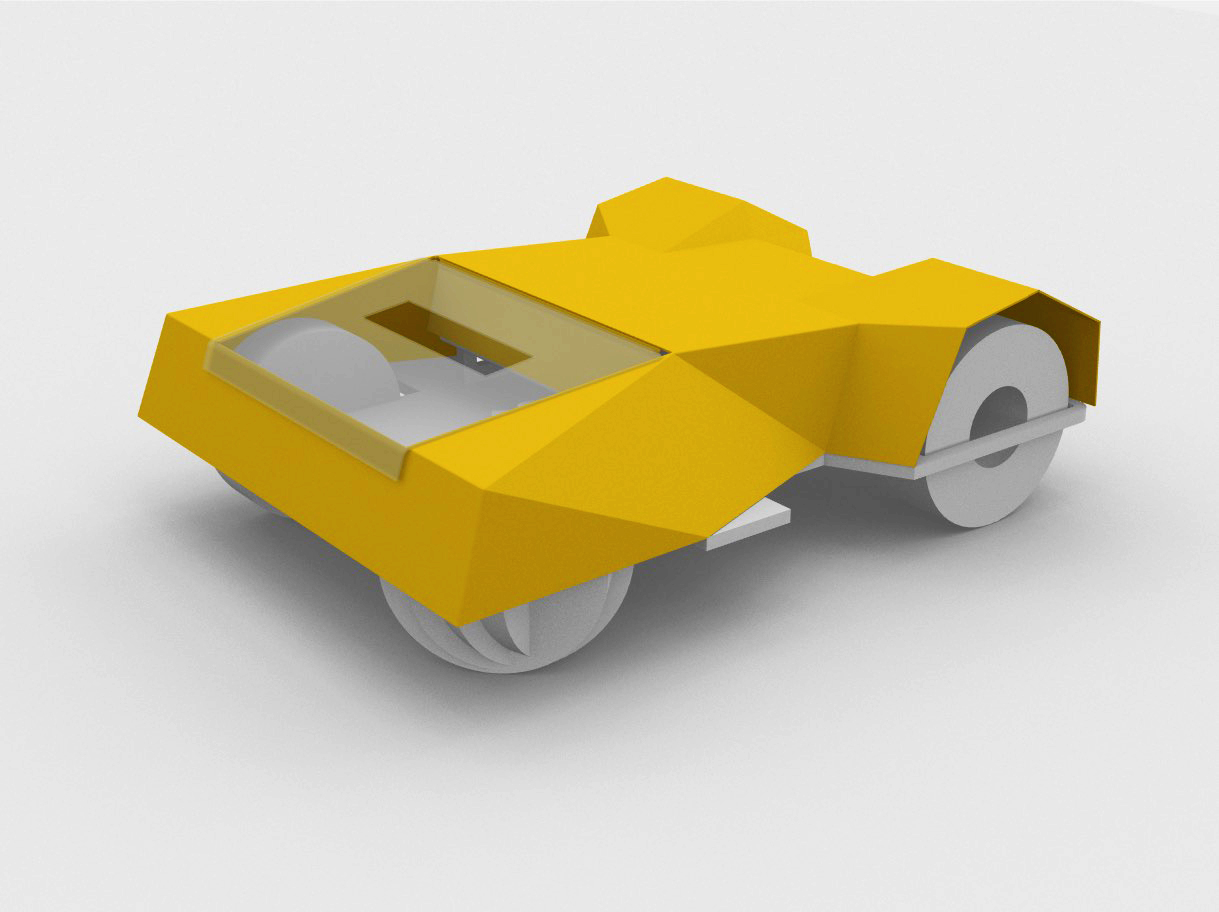

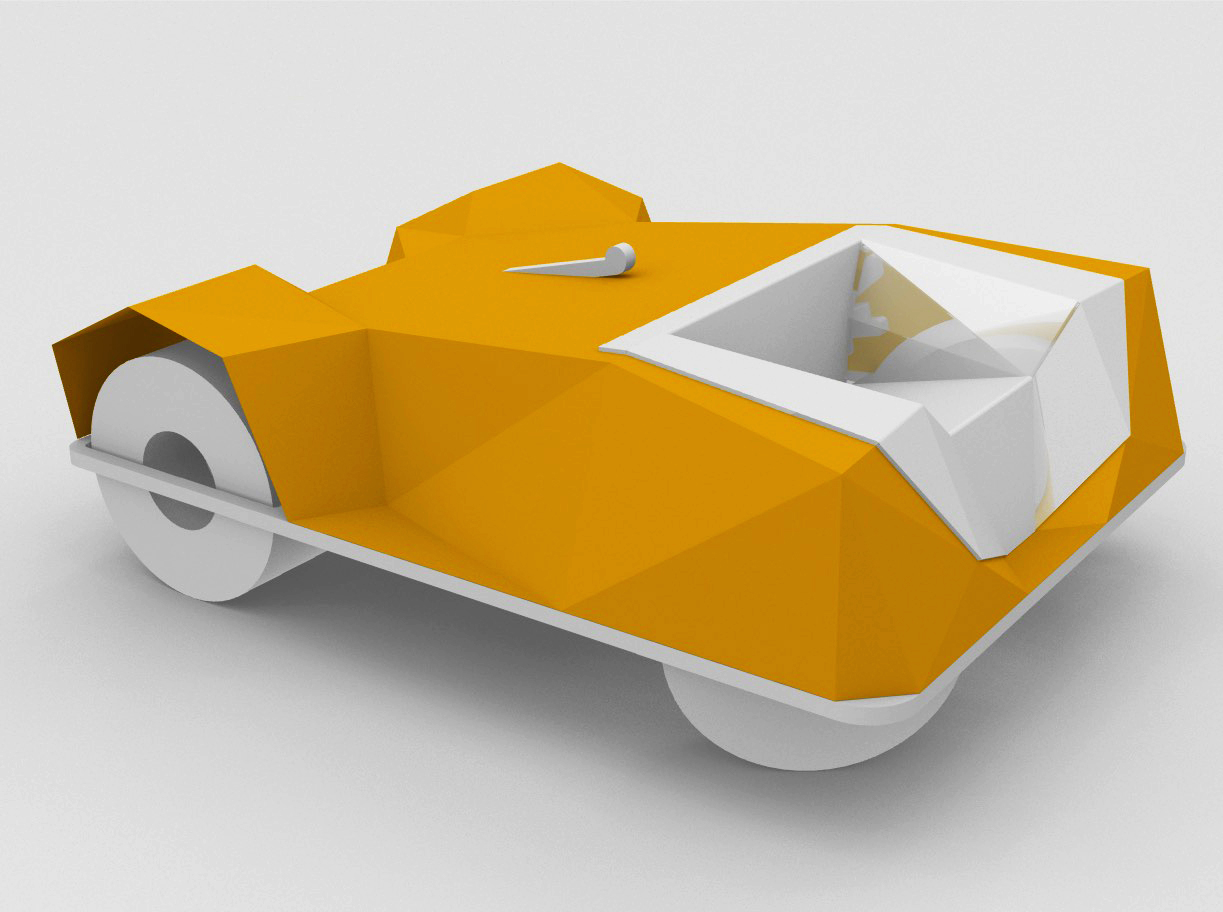

I set out to design a faceted shell with the goal of minimizing the number of necessary facets, while still achieving an exciting shape and working with the design of the chassis and control box. It should perhaps be noted that this project was in 2017, two years before the Tesla Cybertruck reveal.

Some sketches brainstorming early concepts for form:

An early iteration:

I created a quick foam and paper model to share with teammates and test fit:

It was quickly obvious from this model that it would make removal of the control box difficult, as the through hole was too small, and hard to fit one's hand into, so future iterations moved towards a larger front section of the shell.

Final Iteration:

Video of milling the thermoform mold:

Thermoforming:

Completed Fleet:

Avisly

Custom Heat Therapy Masks

Avisly is a therapeutic heating face mask for people with trigeminal neuralgia(TNG) - a condition which causes chronic and / or acute pain in areas of the face. I started this project because my mother, Mia, developed trigeminal neuralgia, and was faced with no existing medical resources to help her manage her pain without relying on mind-numbing painkillers.

Being an engineer herself, by the time I started this project Mia had already created many of her own solutions:

Because of the chronic nature of TNG pain, Mia needs to wear a mask for large parts of the day, meaning she is often wearing one in public. The masks sometimes make her a target for unwanted glares or social discomfort.

My goal with Avisly was to make a mask that would be almost invisible.

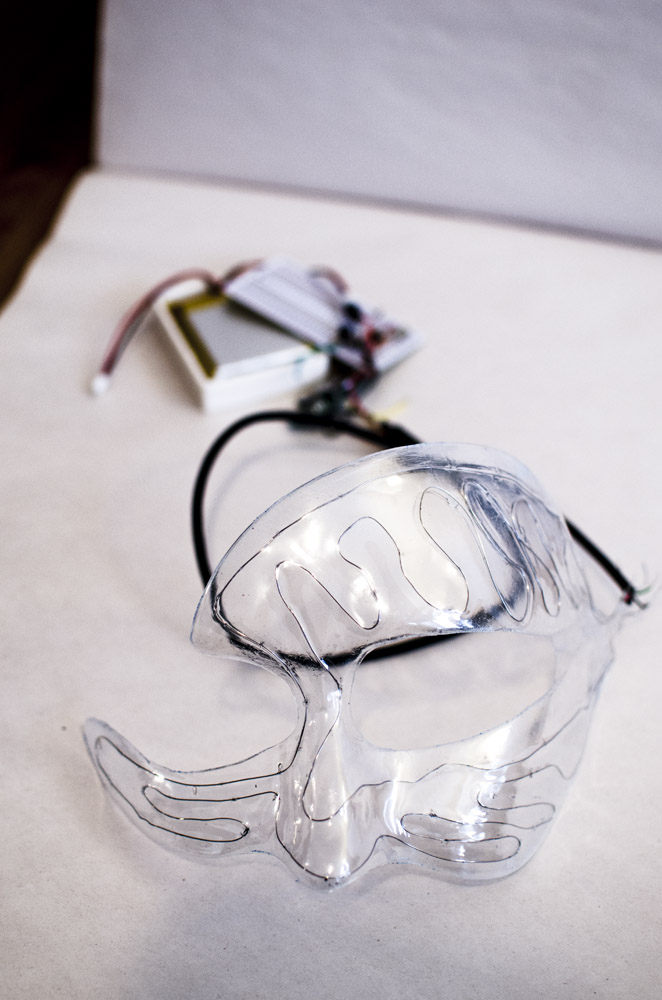

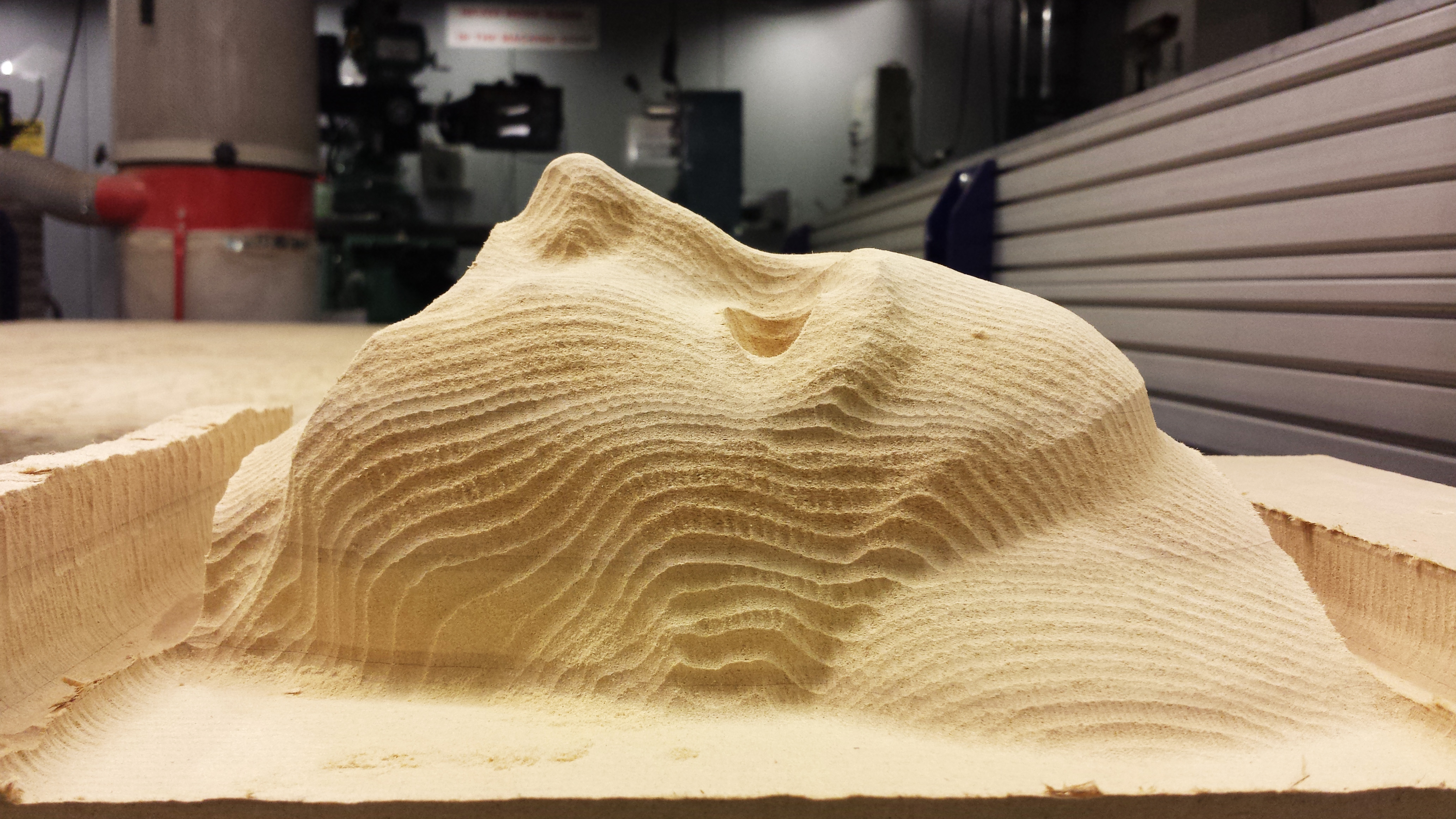

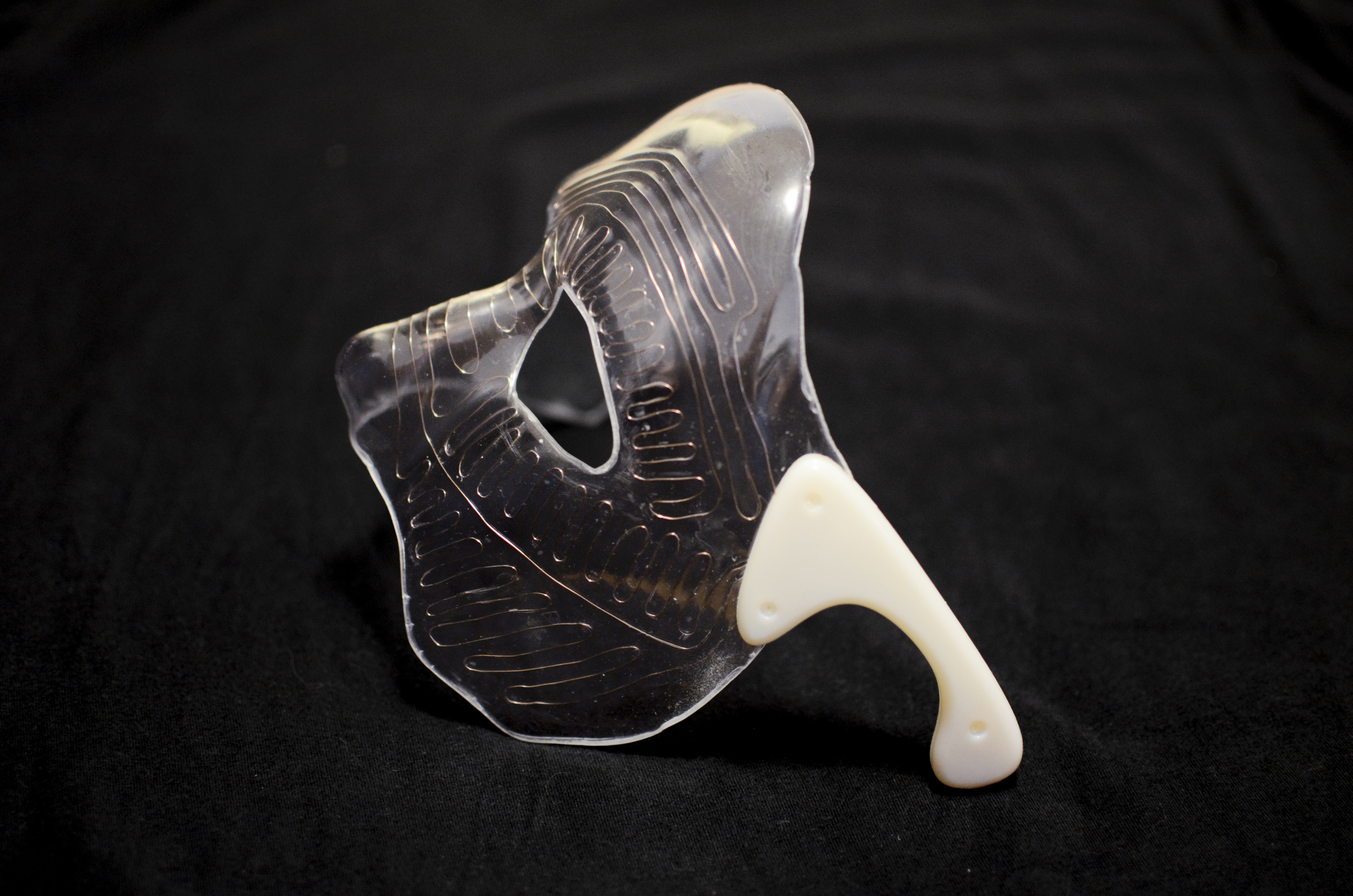

Using 3D scanning and CNC milling, I created a custom mold on which to thermoform masks, which allowed us to use clear materials (PETG). I used cuprothal wire as a heating element and secured it by thermoforming a second time over the wires.

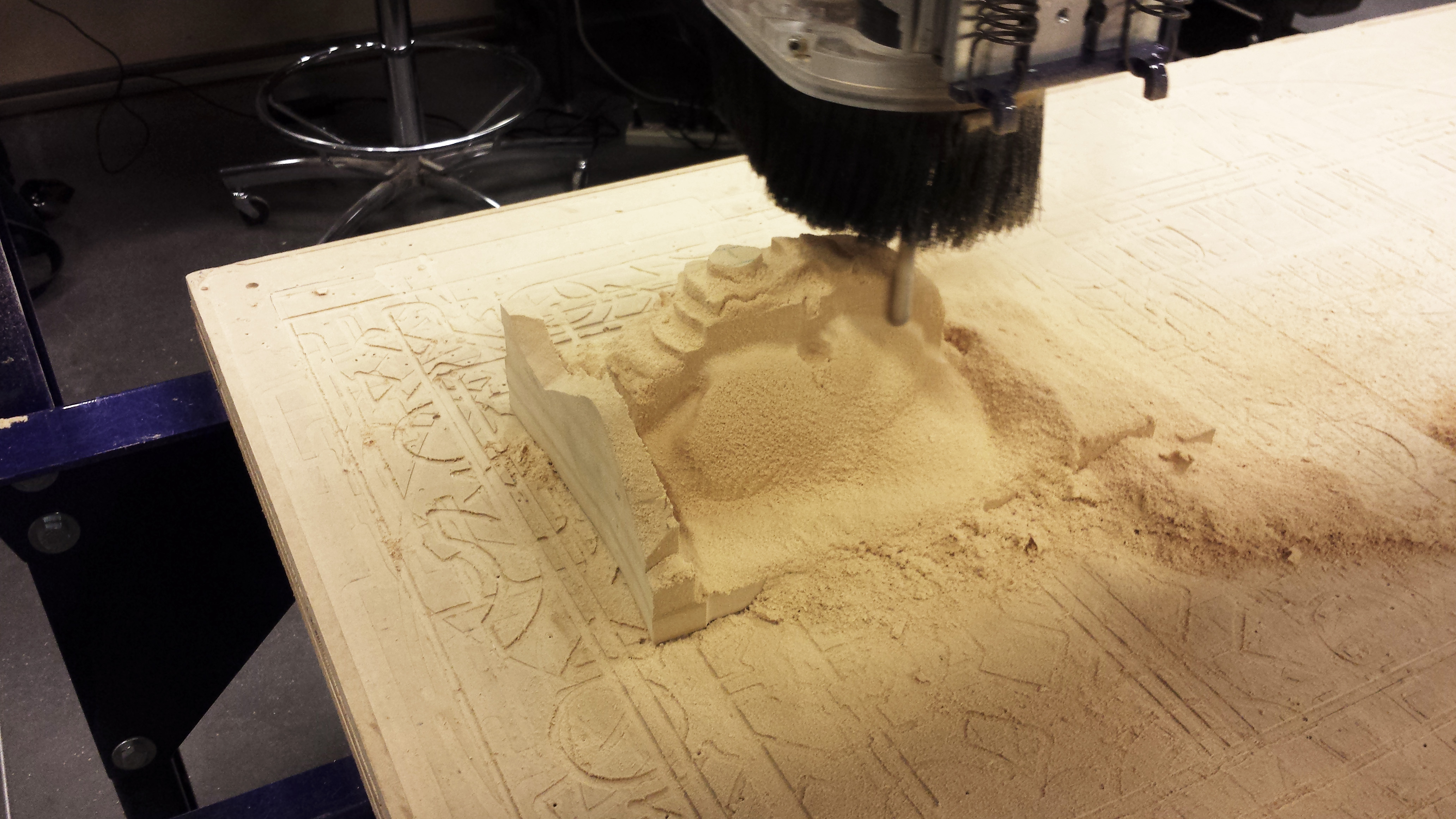

Milling out the mold:

After a lot of sanding, priming, and sanding and priming again, the mold was ready for thermoforming:

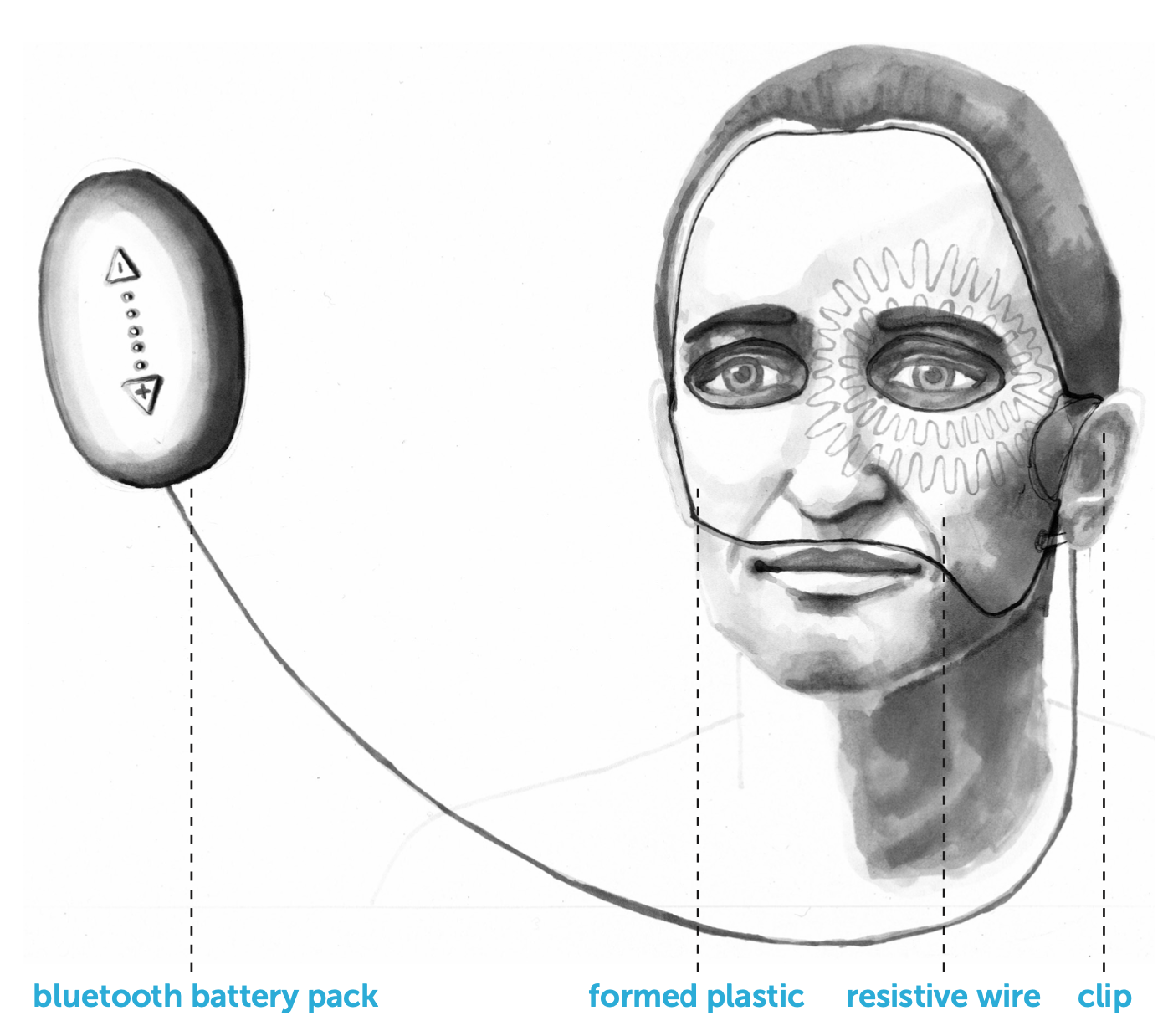

Beyond the custom mask and its integrated heating coil, Avisly also needed a system for powering and controlling the heat output of the coils. I designed a battery pack that could easily and comfortably be slipped in a pocket (or as Mia suggested in a bra), as well as an over-ear plastic enclosure to protect the fragile interface where heating wires exit the plastic mask and are connected to power:

Future Ideation:

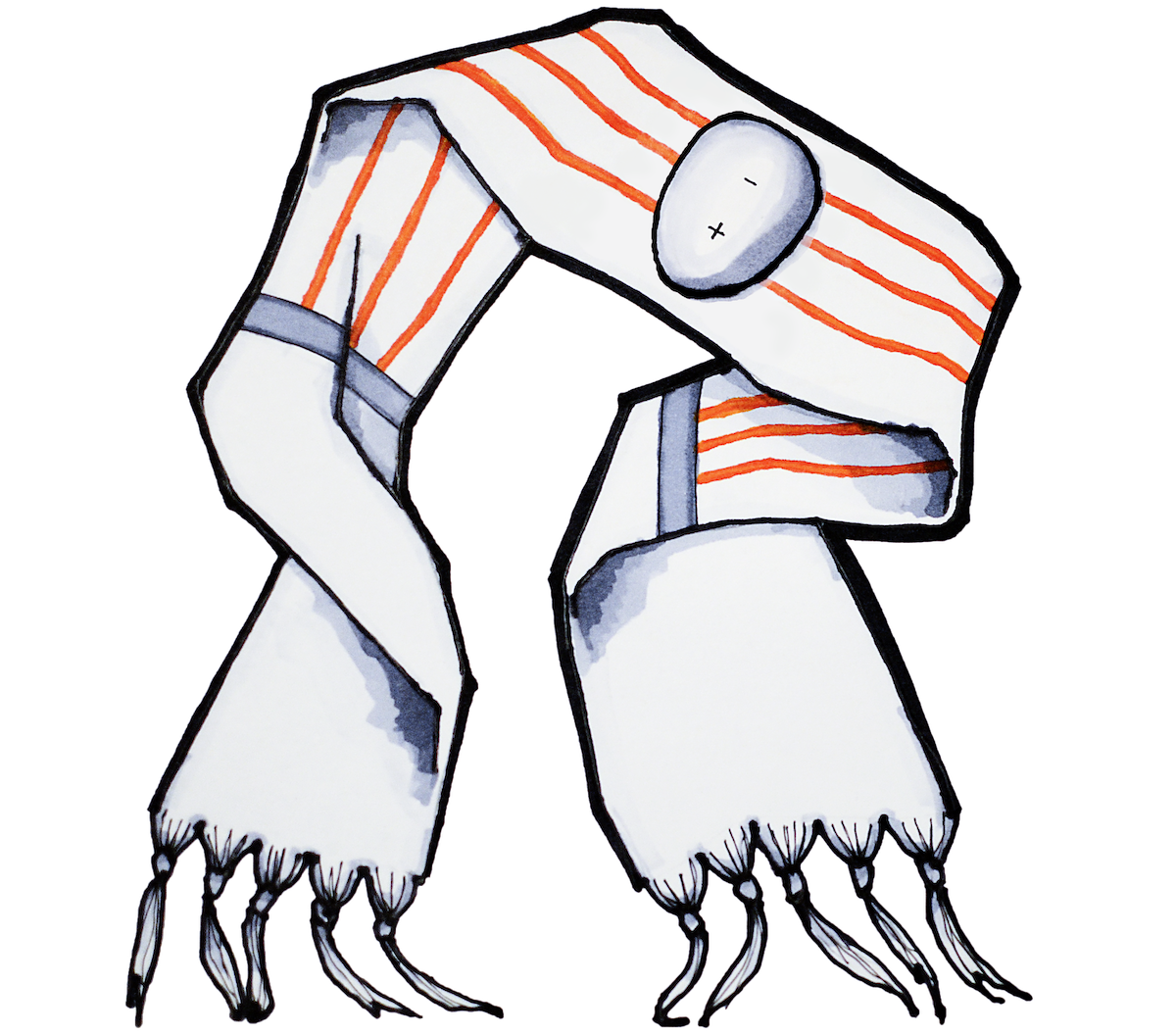

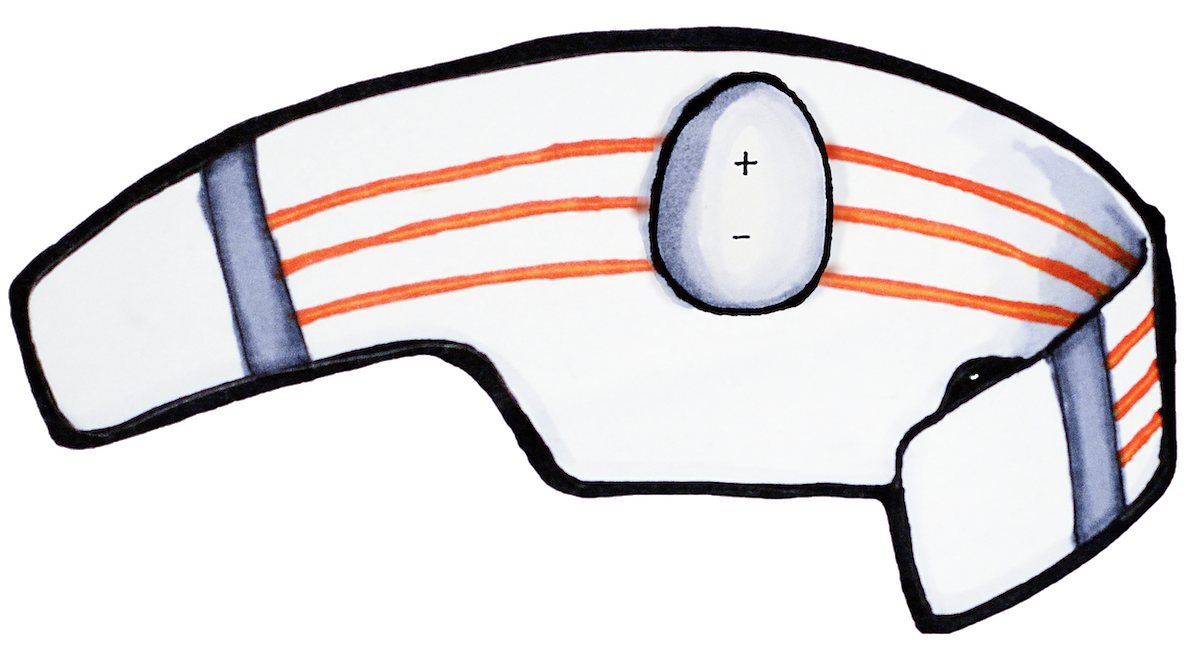

After completing the latest iteration of Avisly and seeing how thin heating wires could be, I imagined being able to integrate heating wire into garments, and created these marker renderins of a glove, scarf, and back brace:

Previous Generation:

If you’re curious to see how much the masks improved over time, here are some images of an earlier stage of development, where the heating wires were much thicker, and the mask less defined: