Hardwood Coffee Table

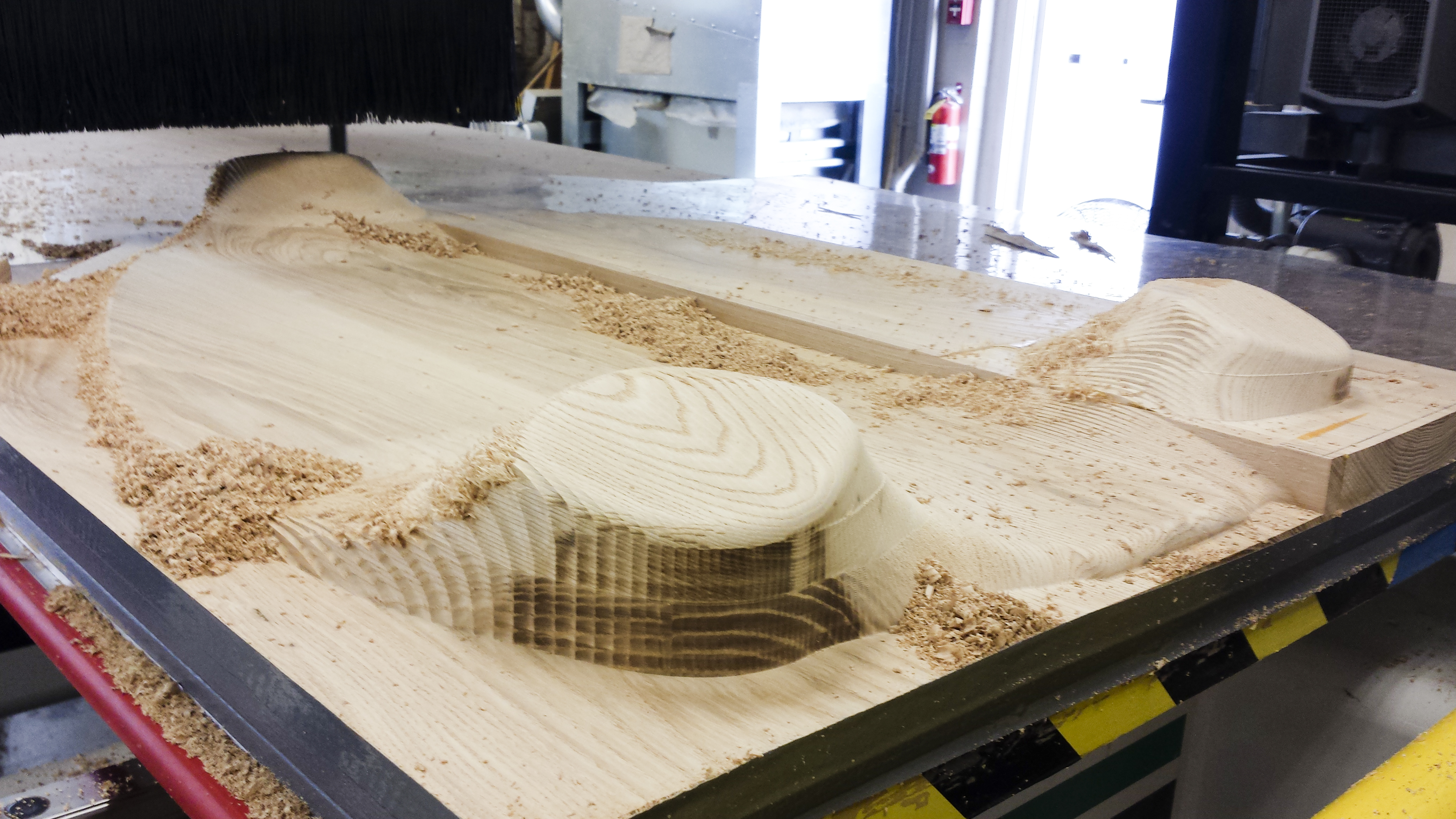

Two identical hardwood coffee tables, one ash and one cherry. Made for a digital fabrication class, these tables were designed to test the abilities of milling and cad technology in a typically manual process. The table tops are joined and glued, then milled into the shape that meets 3 table legs, requiring several tool sizes for different geometries. The legs are each milled on a 4 axis shopbot (a mix between a mill and a lathe). Due to their large circumference in some areas, the legs had low margin for error and required precise roughing cuts before milling.

The legs are then fitted into the table top with a mortise-tenon joint and the table is planed, sanded, and finished.

The final product:

Well, almost. In these images the tables haven’t yet been oiled, and there remains some sanding to be done - mostly on the feet.